Overview

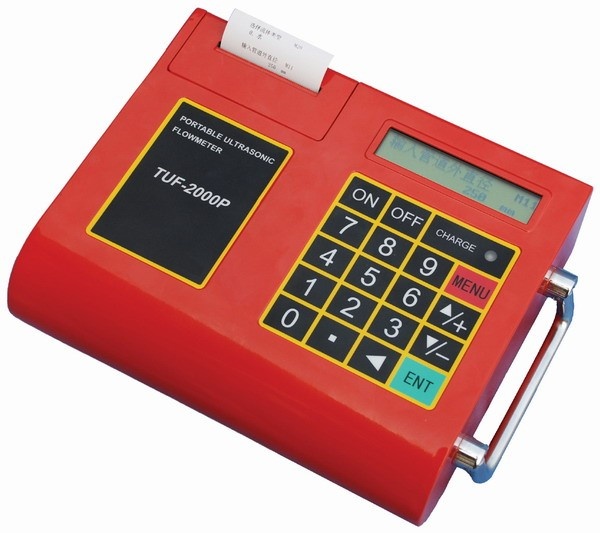

The TUF-2000P flow meter incorporates the latest ICs manufactured from the famous semiconductor manufacturers like Philips, Maxim, TI, Winbond, and Xilinx. The hardware features the ease of operation, high accuracy and outstanding reliability, while the software provides a very user friendly interface and much more functions. It employs a patent balanced lower voltage multi-pulse igniting circuit which increases the anti-interference ability magnificently so that the flow meter will work properly even in demanding industrial environments such as those with power frequency transverter working nearby.

Sensor

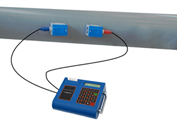

|

Clamp On

|

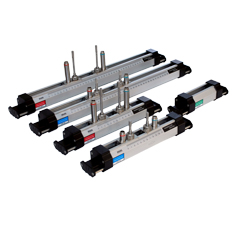

Mounting Bracket

|

|

|

|

| Clamp On Sensor |

Clamp on sensor with the magnet, you can install the transducer very easily when

measuring the carbon steel pipes and iron pipes,no need cut off water and no pressure loss |

|

|

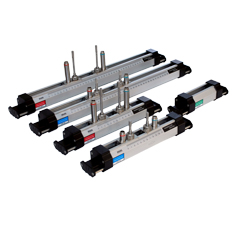

Mounting Bracket Sensor

|

The fixtures and slides adopt full aluminum material,with the feature of light weight and firm structure.The Metric/British system scale can improve installation accuracy.

|

|

Main Features

Wide measuring range

Several types transducer for selection, pipe size from Dn15mm to Dn6000mm

Large capacity battery

Built-in rechargeable Ni-MH battery, provide over 12 hours of continuous operation

Built-in data logger

Instant print, uplink over 20 measuring data to computer or internet

Data storage

Measuring results can be stored on SD card, easy for the data analysis and statistics

RS485 communication interface

Easy for the data transfer

Input and output signal

Output signal: 4-20mA, pulse signal, relay signal

Input signal: three way 4-20mA

Technical Parameters

|

Item

|

Performance and Parameter

|

|

Convertor

|

Principle

|

transit-time ultrasonic flowmeter

|

|

Accuracy

|

Flow: over 1%-2%(battery-powered supply over ±2% ),Heat: over ±2%,Repeatability: over 0.2%

|

|

Display

|

4×1 6 character LCD with backlight, support the language of Chinese, English and Italy

|

|

Data Record

|

Mini thermal printer with 24 line character output, or 2G SD card

|

|

Signal Output

|

1 way 4~ 20mA output, electric resistance 0~ 1K,accuracy0. 1%

|

|

1 way OCT pulse output( Pulse width 6 ~ 1 0 0 0 ms,default is 2 0 0 ms)

|

|

1 way Relay output

|

|

Signal Input

|

3 way 4~ 20mA input, accuracy 0. 1%,acquisition signal such as temperature, press and liquid level |

| Connect the temperature transducer Pt100, can finish the heat/energy measurement |

|

Data interface

|

Insulate Rs232 serial interface, upgrade the flowmeter software by computer

|

|

Pipe Condition

|

Pipe Material

|

Steel, Stainless steel, Cast iron, Copper, Cement pipe, PVC, Aluminum, Glass steel product, liner is allowed.

|

|

Pipe Diameter

|

25---6000mm

|

|

Straight length pipe

|

Transducer installation should be satisfied: upstream10D, downstream 5D, 30D from the pump.

|

|

Measuring Medium

|

Type of Liquid

|

Water (hot water, chilled water, city water, sea water, waste water, etc.); Sewage with small particle content; Oil (crude oil, lubricating oil, diesel oil, fuel oil, etc.); Chemicals (alcohol, acids, etc.); Plant effluent; Beverage, liquid food; Ultra-pure liquids; Solvents and other liquids

|

|

Temperature

|

Standard Transducer: -30--90℃; High-temperature transducer: -30--140℃

|

|

Turbidity

|

Under 10000ppm and less bubble

|

|

Flow rate

|

0--±7 m/s

|

|

Working Environment

|

Temperature

|

Main Unit: -20--60℃

|

|

Humidity

|

Main Unit: 85% RH Flow Transducer: Ip67

|

|

Power Supply

|

3 AAA built-in Ni-MH batteries 1.2V(for over 12 hours of operation). 90V-260V AC adapter

|

|

Power Consumption

|

1.5W

|

|

Industrial Online Water Analysis

Industrial Online Water Analysis pH/ORP Meter

pH/ORP Meter